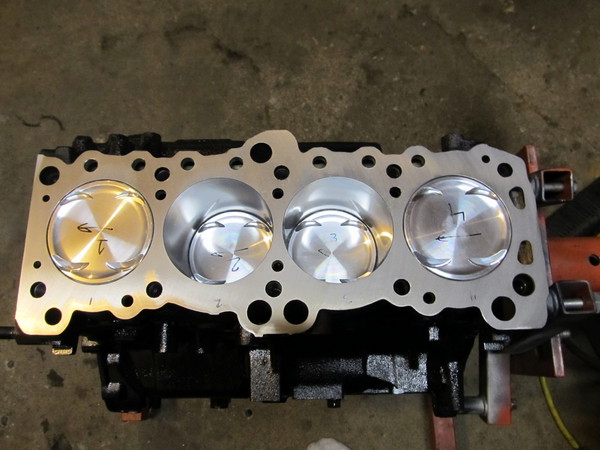

I only had the 8 locks to install, so not much for practice runs. I did have 2 pop out but by the 4th piston I had the hang of it.

I am happy with all the specs on the bearings, rings, piston to wall, crank end play, etc. I just have a few things to touch up on the head and I am waiting on a few other parts, oil pump, water pump stuff that should be here the end of this week. All in all I had 10 hours into the short block for final spec and assembly. Not bad but I wanted to make sure everything was as good as it could be.

Then when the car is up and running I will start to work on the back up motor. If everything works out I could be at the DB spring dyno day in mid May, then its off to Grove Creek for 60' testing.

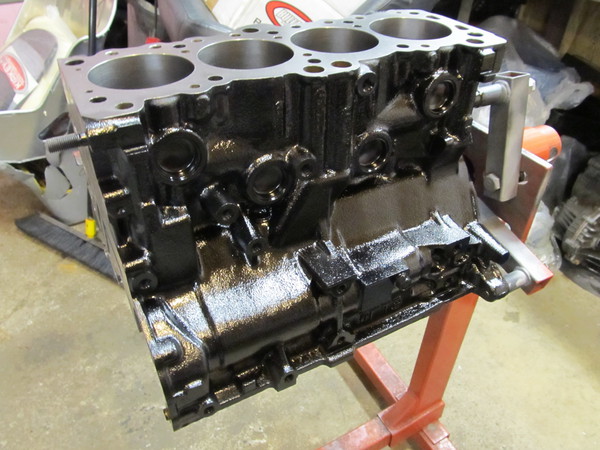

After a fun threw the parts washer at work, then hot water and dawn dish soap wash, then brake clean and brushes threw the oil galleys and cylinder walls. A fresh coat of primer, then black engine paint and clear coat to finish it off.

Here are most of the tools and parts needed to assemble the short block, thanks to CP pistons and Carrillo rods for the great parts, and the Kramm Lox just make the piston and rod assembly so easy.

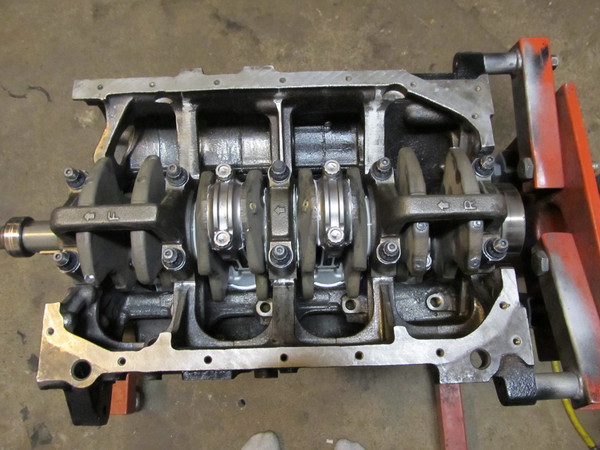

Here are the ARP main studs installed with the custom main cap dowel pins that are 1/2 in the block and 1/2 in the main cap. I am using STD sized ACL race series main bearings, and ACL race series rod bearings with the added .001" oil clearance.

Here I take the custom Carrillo rod and check the rod bolt length before I un-torque the bolt, this lets me know how much rod bolt stretch there was when they did the hone on the big end of the rod. I measured an average .0035" of rod bolt stretch, a common number for a 4g63 rod bolt right out of the box. I then measure the bolts free length, this will let me know over time if the bolt stretches and does not go back to its original length. Then I install the rod bearing shells and check the ID of the bearing. I torqued the rod bolts to 58 fl/lbs and the rod bolt stretch was about .0055" so just above the bottom end of the spec, which is .004"-.007".

Then I install the Kramm Lox for the wrist pin, and after file fitting the rings I install each rod/piston combo into the block and properly torquing the rod bolts 1 last time. I torqued them all to 58 ft/lbs again and only had to put a little more on 1 rod bolt to get in the .006" rod bolt stretch, right in the middle of the spec.

~John