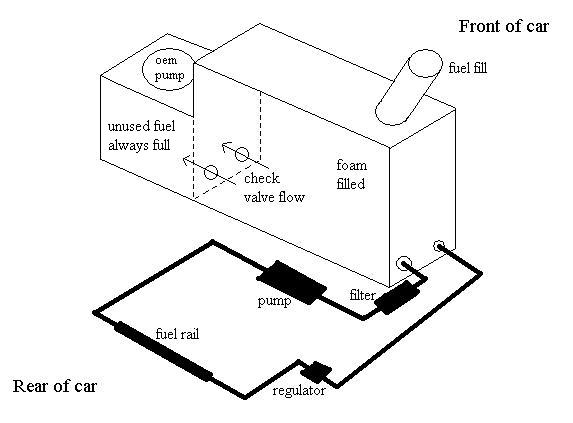

Ok I made some better drawings to help visualize how this aftermarket tank works, these drawings are with a view from the rear of the car. I think I understand the risks of having a single pump pull from two areas, if one side went dry it would suck in both air and fuel and could have bad results.

Here is the existing setup, I think the person who did this setup had the right idea, they just put the pump on the wrong side of the tank. The driver's side has the check valves so fuel can enter that side but not come out. I believe this is why my fuel gauge always reads full no matter what, because that area got full and can never be emptied from the right side.

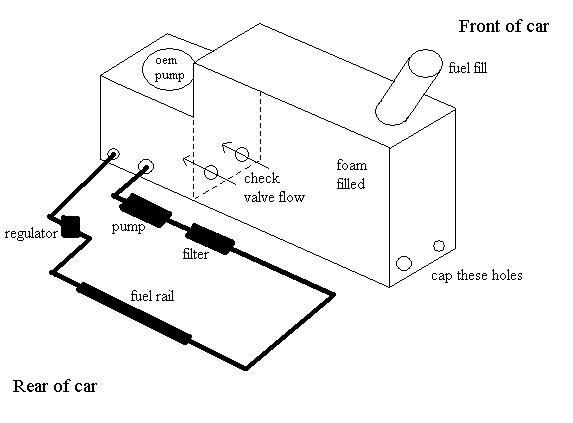

Here is proposed solution 1. It retains the sump setup with external pump and filter, but it pulls from the rear center portion of the baffled area, and returns to the same section. Don't mind the reverse fuel flow, I just did that for ease of drawing.

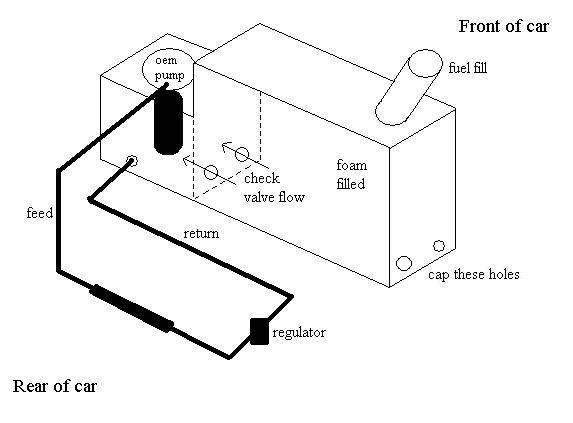

Here is solution 2. It puts an internal pump in the OEM location (without the internal regulator), and the return line is plumbed back into the baffled location.

Are there any benefits to running an external sump pump vs an internal pump? The only difference in labor is having to weld an extra bung but that is trivial since I need one for the return anyway. I have the hardware for the sump setup but an internal 255 is cheap.

Thoughts?